The Austrian Material Foresight study was carried out in order (a) to underline and strengthen the awareness by the most important stakeholders for materials research and materials production in Austria, (b) to initiate and support innovative actions in structural material developments, and (c) to open new ideas and concepts beyond the already supported topics so that the research site and manufacturing base in Austria receive more foundation.

Challenges in the Austrian Manufacturing Industry

The Austrian manufacturing industry has been faced with off-shoring of production sites, low growth rates in Europe, limited availability of raw materials, and increasing costs of resources, with a simultaneous dumping on the domestic market. All these factors have been accompanied with changes in the value system of the society and with stricter legal regulations in recent years. To avoid these obstacles, a stronger focus on research and innovation is required.

Traditionally the Austrian economic power depends on the production and processing of materials, and a big share of the value chain is influenced by materials technology. Materials belong to the so called “enabler technologies” and lay the basis for innovations in automotive, aviation, machine engineering, ICT, medical technology and many other industries. Especially the steel industry plays a key role in Austria, represented through a highly specialized foreign trade with a focus on machines, production facilities and vehicles.

High-performance Materials and Products in the Future

The Austrian Ministry for Transport Innovation and Technology initiated the study “Austrian Material Foresight” in order to examine possible strategies to support Austria’s position in the segment of high-performance materials and products in the future. Main objective was to develop future scenarios (horizon 2030) for the high-tech materials sector in Austria involving the expertise of universities, industry and organizations. Following aspects were particularly considered:

- Identification of key factors and drivers for the progression of the materials industry and materials research in a national, European and global context.

- Characterization of robust trends in the materials industry and research.

- Illustration of Austria’s special role in future materials industry and research.

- Building a basis for the co-creation of future European materials industry.

Future Scenarios as the Core of the Process

The Austrian Society for Metallurgy and Materials (ASMET), the Montanuniversität Leoben, and the AIT Austrian Institute of Technology GmbH designed and accomplished the project “Materials Foresight” for developing scenarios for the manufacturing bases in Austria. The challenge was to address all four structural materials such as steel, non-ferrous metals, polymers, and ceramic each regarded together with their composites for high-tech technologies along the whole value chain.

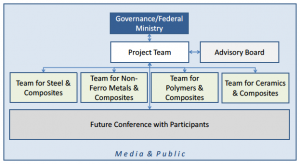

The methodology for the project (see figure 1) was based on the organizational structure with the core project team, the advisory board, the expert team, the procedure for the whole project and the process applied in the workshops, and the involvement of a broader community via conference and the media.

Figure 1: Organizational structure of „Austrian Materials Foresight“

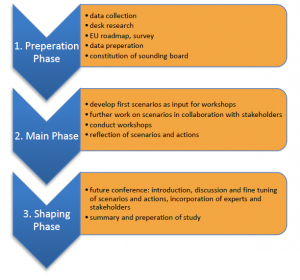

The work was organized in three phases. Figure 2 presents the main tasks in each phase. It shows the development of future scenarios as the core of the process, accompanied by an environmental analysis, by constructive discussions with the advisory board, and the future conference and constitutive work with stakeholders.

- The preparation phase contains the collection of future trends and challenges within an environmental analysis. The Austrian situation with terms of implementation, the results of a roadmap of high performance materials, the participation of Austrian institutions in the seventh EU Framework Program, and the current national funding program on intelligent production (FFG Funding Program Production of the Future) were described and key factors were identified. To structure the key factors of the project team works with a STEEP analysis. Based on the results of the preparation phase, the scenario workshops are designed.

- In the main phase, scenario workshops on steel, nonferrous metals, polymers, ceramics and their composites were conducted together with representatives from the materials industry, materials science, the economic chamber and clusters, and the government. The previously identified key factors with the highest value for influence and uncertainty were chosen for the projection process, where the workshop participants in smaller groups worked out the projection of the selected key factors for 2030. For each materials group, the future products and the research topics were derived from the scenarios. Additionally, measures necessary to achieve the future perspectives were suggested by the participants of the workshops.

- In the shaping phase, the results of the workshops were analyzed and summarized in order to prepare for the discussion with experts in the first Austrian Future Conference on Materials. More than 300 participants of the conference were informed and attended discussions, which helped to disseminate awareness, results, and new ways of thinking. A press conference aimed to create awareness of the problems and results in the media. In a last meeting with the advisory board and some further experts a plan for the next steps was worked out.

Figure 2: Three phases of „Austrian Materials Foresight“

Key Factor: Energy

The assessment of the key factors as a summary of all four materials fields shows that energy (in availability and hence in price) is the most important factor for the materials industry. The cost effective availability is the second most important factor, which influences research and production of materials technologies. Rank three is a political issue, namely the public support in research. The next important factor is the value development of society. The values of a society have thus a big influence on the materials technologies. The fifth rank goes to economic growth, followed by factors like environmental legislation, qualification, financial market, globalization, and production and manufacturing.

The cross-section research topics play an important role in each of the four materials fields (steel, non-ferrous metals, polymers, ceramic). Advanced materials 2.0 means a next generation of materials with new features, also new hybrid materials with new applications. Advanced materials 2.0 presents the biggest share of all cross-section topics, followed by sustainable materials and recycling. The third rank goes to continuous materials improvement followed by innovative flexible manufacturing processes and then energy efficiency in production. Testing for materials and production and modeling and simulation are also important cross-section topics.

From Concept to Impact:Strengthening the Materials Community

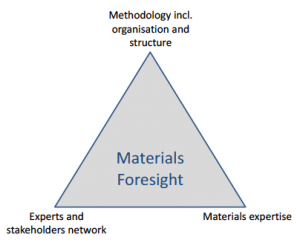

Besides the long-term verified scenario planning, this specific foresight proves that a very well‐developed concept can be a key success factor for the whole process. The excellence in each of the three aspects of the concept, methodology expertise, materials expertise, and network and knowledge about the stakeholders in materials industry, in materials science, as well as in politics and how one can get support from the most influential people is one of the building blocks for the success of this project.

Figure 3: Scheme of project concept

The three aspects in figure 3 were well represented in the project with the Austrian Society for Metallurgy and Materials (ASMET) with focus on experts and stakeholders networks, the Montanuniversität Leoben with the competence in materials, and the AIT Austrian Institute of Technology with methodology experience. However, the cooperation of all three organizations and the willingness to learn from each other made the project successful and strengthened the “materials” community.

Furthermore, the project could help to create awareness in this community as well as in the funding agencies and the ministry for what is already funded and supported by the national funding system, and also for what is still missing in the funding programmes. A follow-up project will be dealing in particular with working out and assessing research and project ideas with the potential for disruptive innovation. The addressed community during the foresight is also supporting the impact for disruptive innovation in the future.

| Authors: | Marianne Hörlesberger marianne.hoerlesberger@ait.ac.at

Bruno Hribernik bruno.hribernik@voestalpine.com Brigitte Kriszt brigitte.kriszt@unileoben.ac.at André Uhl andre.uhl@ait.ac.at |

||||

| Sponsors: | FFG (The Austrian Research Promotion Agency) on behalf of Austrian Ministry for Transport, Innovation and Technology | ||||

| Type: | National Foresight Project | ||||

| Organizer: | ASMET (Austrian Society for Metallurgy and Materials); Bruno Hribernik | ||||

| Duration: | 2013 – 2014 | ||||

| Budget: | € 150,000 | ||||

| Time Horizon: | 2030 | ||||

| Date of Brief: | February 2016 | ||||

Download EFP Brief No. 259: Austrian Materials Foresight

Sources and References

This brief is based on the following article, in which the findings are discussed in more detail:

Hörlesberger, M., Kriszt, B., Hribernik, B. (2015). Foresight for the Enabling Technologies Materials. In: Pretorius, L., Thopil, G., (eds.) Graduate School of Technology Management, University of Pretoria, Proceedings of the 24th International Association for Management of Technology Conference, 08th – 11th June, Kapstadt, pp. 449-464.

Hribernik, B.; Kriszt, B.; Hörlesberger, M. (2014). Foresight für Hochleistungswerkstoffe zur Stärkung des Wissens- und Produktionsstandortes Österreich. Study on behalf of BMVIT. (http://asmet.org/austrian-materials-foresight/)

References

Cuhls, K. (2012). Zukunftsforschung und Vorausschau. In: FOCUS‐Jahrbuch 2012. European Foresight Platform (efp). ForLearn. http://www.foresightplatform.eu/community/forlearn/.

Geschka, H.; Von Reibnitz, H. U. (1983). Die Szenario‐Technik ‐ ein Instrument der Zukunftsanalyse und der strategischen Planung. In: Töpfer, A. und Afhelt, H. (Hrsg.): Praxis der strategischen Unternehmensplanung; Frankfurt/Main: Matzner; S. 125‐170.

Keenan, M. (2002). Technology Foresight: An Introduction, Institute of Innovation Research, University of Manchester, UK.

Martin, B. (2001). Technology foresight in a rapidly globalizing economy.

Martin, B., R. (2010). The origins of the concept of ‘foresight’ in science and technology: An insider’s perspective. IN Technological Forecasting & Social Change, 77, 1438–1447.

Miles, I.; Keenan, M. (2003). Overview of Methods used in Foresight, in [UNIDO 2003].

Von Reibnitz, H. U. (1992). Szenario Technik: Instrumente für die unternehmerische und persönliche Erfolgsplanung, Wiesbaden: Gabler Verlag.